Fiberglass blending filter bag

Description

Compared with fiberglass filter bag, Fiberglass blending filter bag has obvious improvement in abrasion resistance, flexural strength and peeling strength, and can bear high filtration load.

Material :

Fiberglass compound staple fiber, P84 fibre, Nomex fiber

Characteristic

The filtration speed can reach 1.0m/min, and the running resistance is low. Compared with synthetic chemical fiber high temperature resistant filter material, to overcome the large chemical fiber filter material elongation, large deformation, low temperature resistant, corrosion resistance and weaknesses; Better dimension stability, strength, and the price is lower than other high temperature resistant chemical fiber.

Application

Glass fiber composite bag has been widely used in iron and steel, nonferrous metal smelting, chemical industry, building materials, electric power department.

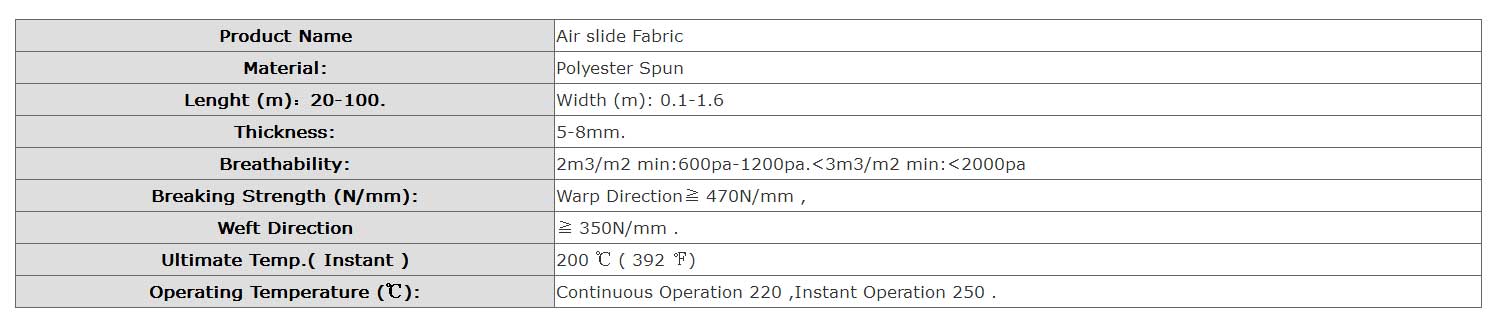

Physical and Chemical Properties of Fiberglass Blending Filter Bag:

|

Fibre Composition |

Glass fiber/ High temperature fiber |

|

|

Scrim Composition |

E-glass fiber |

|

|

Weight |

>900 |

g/m2 |

|

Thickness |

2.50 |

mm |

|

Mean Air Permeability |

8-10 |

m3/m2/[email protected] |

|

Breaking Strength-CD ( warp ) |

>1800 |

N/5x20cm |

|

Breaking Strength-MD (weft) |

>1800 |

N/5x20cm |

|

Breaking Elongation-CD |

<10 |

% |

|

Breaking EIongation-MD |

<10 |

% |

|

Dry Shrinkage-CD |

< 1 |

% |

|

Dry Shrinkage-MD |

< 1 |

% |

|

Recommended Continous Operating Temperature |

240 |

°C |

|

Recommended Short-term Operating Temperature |

260 |

°C |

|

Finishing |

|

|